Nakazato: Sustainable, durable and timeless clothing in partnership with Epson

Inkjet fabric printing has a much smaller environmental footprint than conventional textile printing, as it uses only a percentage of the amount of water

Fashion house Yuima Nakazato has a vision that the evolution of clothing will create an even richer future.

To fulfill its responsibility for the future, the fashion house continues to carefully select the materials used and the sources from which it obtains them. He has always tried to create clothes that are designed to be used for a long time and then recycled.

Epson supports Yuima Nakazato’s vision and recently used digital printing technology on fabrics to support the reproduction of the fine textures and colors of handwriting, in line with the fashion house’s demanding requirements, as well as the production of works with reduced environmental impact. Yuima Nakazato’s designs were faithfully reproduced in ultra-thin (0.07 mm) silk organic fabric that was used for some of the fashion pieces using a Monna Lisa digital inkjet printer for printing on fabrics, at the Solution Center of Epson’s Fujimi plant.

Digital printing of fabrics does not require printing plates, so it is ideal for the rapid production of material only in the required amount.

As these designs were printed with pigment ink, which requires fewer steps than the printing process than paint ink, Yuima Nakazato was able to work on the designs for the fashion collection even just before the show.

At the same time, inkjet fabric printing has a much smaller environmental footprint than conventional textile printing, because it uses only a percentage of the amount of water.

In addition to supporting clothing production, Epson also supported scenography using digital printing technology in the production of paper sculptures. These sculptures were important elements that helped create the blue-themed vision of the collection.

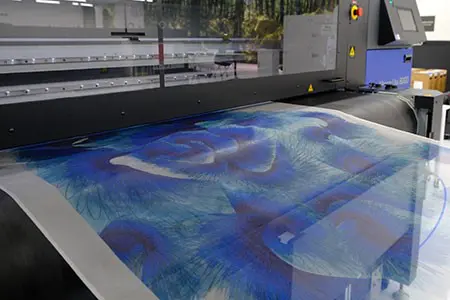

The entire scene was shrouded in images of the Earth hand-painted by Yuima Nakazato. These images were enlarged and printed on a total of 832 square meters of printing paper, using an inkjet PRINTER SC-P20050 at the LFP Solutions Center at Epson’s Hirooka office.

Constructions were used to support the printed paper to create the three-dimensional works of art in the stage space.

The support structures were created from in-house paper used within Epson that was processed using the company’s Dry Fiber Technology. Epson has compiled the decorative pieces used for the collection after the end of the demo and plans to discuss their use in other applications with Yuima Nakazato.

Epson is committed to creative partnerships to put into practice a wide variety of its clients’ creations through its initiatives to reduce environmental impact, realizing its vision of achieving sustainability and enriching communities.